A novel concept for photovoltaics that exploits the ability of materials to exist in different crystalline phases

The group of Prof. Yana Vaynzof at the Integrated Center for Physics and Photonic Materials (IAPP) and the Center for Advancing Electronics Dresden (cfaed) at Technische Universität Dresden has demonstrated a novel concept for solar cells that exploits the ability of materials to exist in different crystalline phases. The related study has now been published in the journal Nature Energy.

The purpose of a photovoltaic cell is to convert sunlight into electricity. By absorbing the sunlight, pairs of charge carriers are generated and then need to be guided to the opposite sides of the photovoltaic diode to produce electrical current. To facilitate this process, most solar cells include a heterojunction that provides a favorable energetic landscape to drive the charges to be separated.

For example, silicon solar cells form a heterojunction by electrically doping each side of the device, forming a p-n junction. Organic solar cells, on the other hand, rely on blending different types of materials (donor and acceptor) to form a bulk heterojunction. However, these concepts are often not applicable to emerging classes of novel photovoltaic materials.

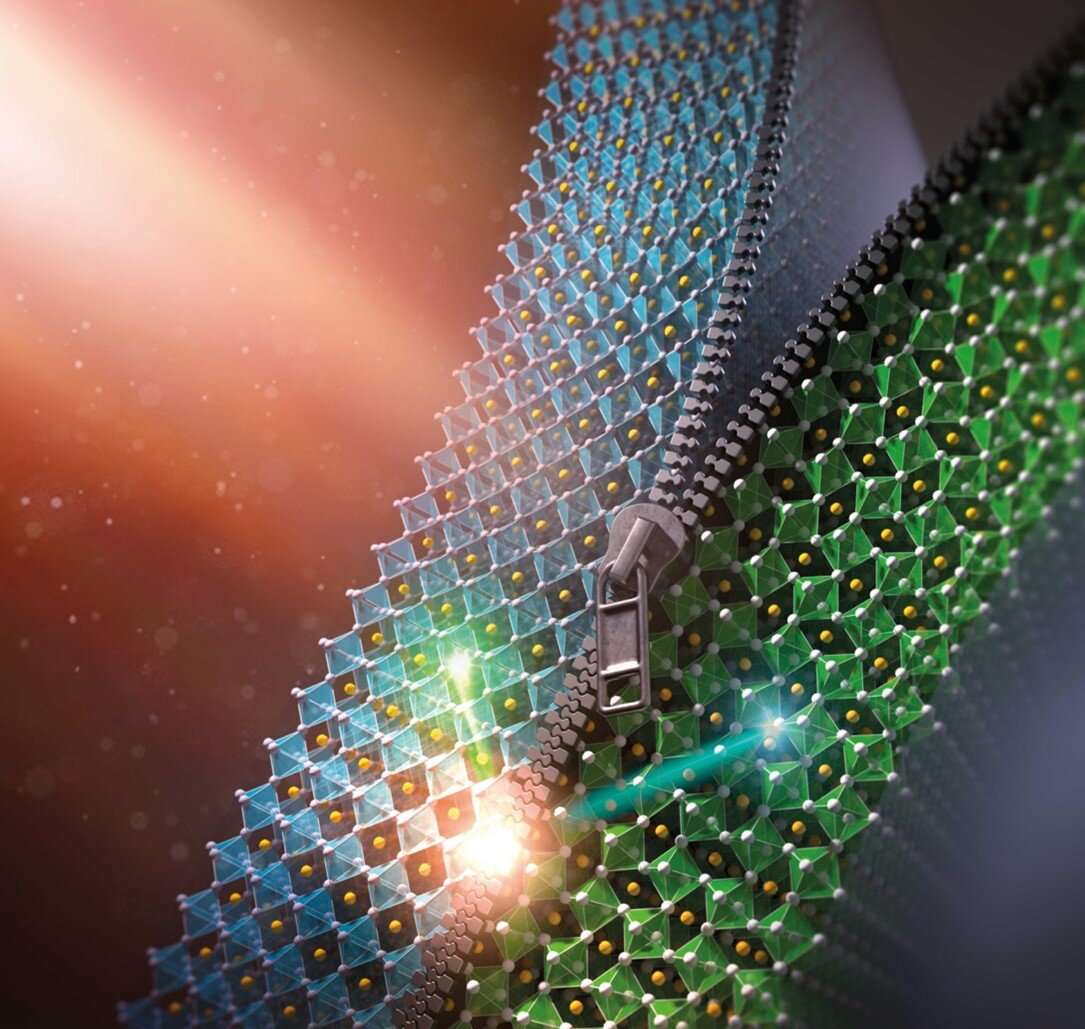

Prof. Vaynzof and her team have now shown an entirely new concept for the formation of a heterojunction for photovoltaics. To do so, the researchers take advantage of the fact that materials can often exist in different structural configurations, termed crystalline phases.

This phenomenon, called polymorphism, means that the same material can exhibit different properties, depending on the specific arrangements of atoms and molecules in its structure. By interfacing two such phases of the same material, Prof Vaynzof and her team demonstrated for the first time the formation of a phase heterojunction solar cells. Specifically, the researchers chose a caesium lead iodide perovskite—a highly efficient solar cell absorber material—in the beta and gamma phases to realize their new concept.

"The optical and electronic properties of caesium lead iodide in its beta and gamma phase are different from each other," explains Prof. Vaynzof. "By placing a gamma-perovskite on top of the beta-perovskite we were able to fabricate a phase heterojunction solar cell, that is significantly more efficient as compared to solar cells that are based on single phase perovskites." The researchers show in their study, that the top layer of gamma-phase influences the performance of the solar cells in multiple ways.

"Even thin layers of gamma-perovskite led to a performance improvement due to the passivation of defects at the surface of the bottom layer. Thicker layers of gamma-phase resulted in significant improvement in all of the photovoltaic performance parameters with the champion device reaching a power conversion efficiency of over 20%," adds Ran Ji, the lead author of the study.

"Advanced spectroscopic analysis revealed that this improvement in performance is associated with increased light absorption and the formation of an advantageous energetic alignment between the two phases," explains Prof. Vaynzof.

Importantly, the researchers confirmed that the phase heterojunction remains stable during solar cell operation and even supresses ion migration in the solar cell absorber, resolving a common problem for perovskite materials.

To realize the phase heterojunction concept, the scientists utilized two different fabrication processes for the top and the bottom layers. This versatile approach opens the path to the formation of other such structures in the future. "We hope that this novel concept combined with a simple fabrication route for phase heterojunctions will be applicable also to a variety of material systems in a range of electronic and optoelectronic devices," says Prof. Vaynzof.

Since many semiconductor classes exhibit polymorphism, the concept could pave the way to entirely new applications that operate based on phase heterojunctions, that can be created from a single material using simple and inexpensive fabrication processes.